A tradition that has been handed down for four generations

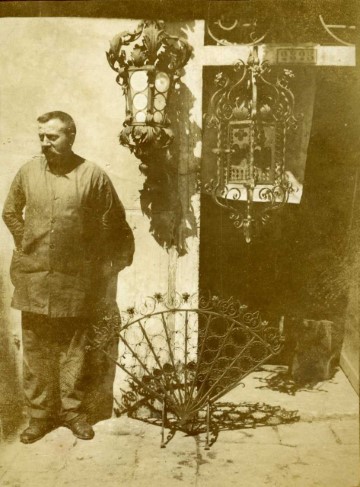

The Gallo company, founded in 1910 by Luciano Gallo, an expert in manufacturing iron lighting and furniture, boasts a very long familiar tradition.

After WWI Luciano moves to Prato (Tuscany) where he starts his own brass and bronze foundry in the historical centre of the town.In the 1950s other material are introduced in the production process of the company such as crystal and Murano glass thus enriching the stylistic appeal of their creations.

During 1970s Aldo Gallo revolutionizes the company’s production by introducing newer materials such as wood, porcelain and ceramic for en even more elegant outcome, so much that the company faces an important commercial success becoming the reference italian manufacturer of such products.

Today the company is led by architect and designer Jacopo Gallo whose personal style and vision helped him make Gallo an international name appreciated still today worldwide after more than 100 years.

Workings

Iron is worked relying on our skilled workmanship typical of Italy and of the province of Florence and of Tuscany that is hot-wrought iron working: this technique is known as “wrought iron” because the iron is hammered when it is hot and then beaten by a hammer until it assumes the desired shape.

The object thus obtained in wrought iron, which is still raw and unfinished, must be processed in this manner before the finishing touches and decorations are added to it.

- The object is “sanded”. The “sanding” process consists in forcefully spraying (with specific spray guns) a jet of sand on the surface, whose purpose is to clean the iron of all the impurities that are formed during the previous hot-turning (welds, burns and the very greasiness of the iron when it is still coarse).

- once it has been cleaned of all impurities, the iron is coated (clean, yet still raw) with a layer of paint to protect it from any future rust formation (or similar inconveniences). This paint is known as the “base coat”, because it is the first protective layer (i.e. base) on which the required finish will then be applied.

Our decorations and philosophy are totally at the service of the project and of the end customer’s desires: we are, in fact, used to working with architectural firms and are therefore very flexible to their requests, reproducing finishes even starting off from a simple rug sample, wallpaper or curtains sent to us by the customer.

The crystal glass we use for our articles is manufactured in Germany, Austria and Egypt.

The difference between Murano glass and crystal: many who are not versed in the trade confuse Murano glass and crystal details.

How can one recognize it in our articles?: The crystal glass assumes shapes that are geometric or at any rate, more clear-cut and precise (like chandelier pendants, for instance), while Murano glass assumes shapes that are looser, more artistic and colorful.